Industry 4.0, or the digitalisation of industrial processes

Bobst is a global player in the field of printing and industrial packaging. The company launched a large-scale Industry 4.0 project with the goal to digitalise its entire production line over the next years.

Industry 4.0 allows machines to connect with each other and the cloud, enabling companies to automate processes further than before. This improved connectivity offers Bobst’s clients greater flexibility and productivity.

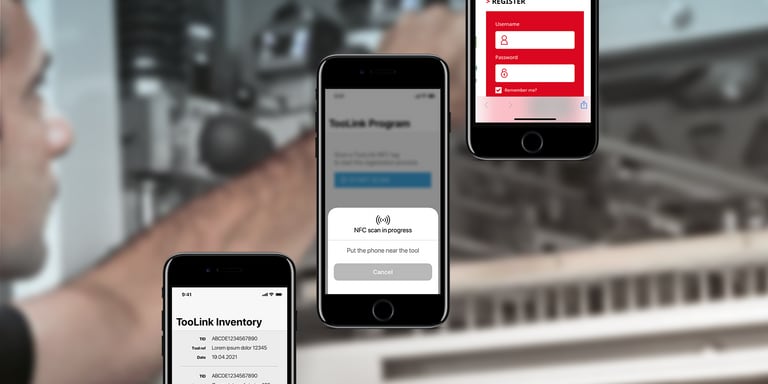

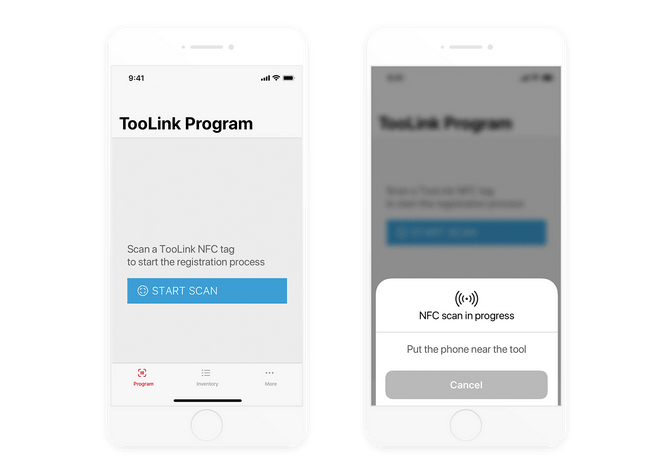

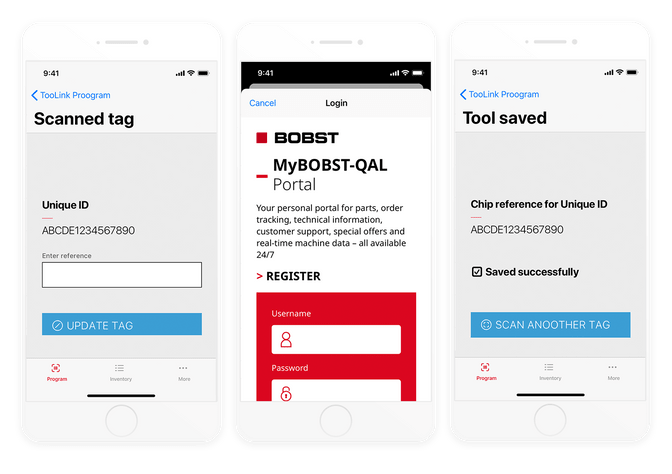

Our project's goal was to fit RFID sensors to the inside of the machines. So the Bobst customers could programme them remotely using the mobile application that utilises the NFC capabilities of smartphones with iOS and Android operating systems.

One month to roll out an MVP

Alexandre de Kalbermatten is part of Bobst Industry 4.0 team at Bobst. He needed specialised know-how in designing and developing native mobile applications.

Therefore, he got in touch with Liip at the end of 2020, asking for a first release at the end of January!

The challenge of working with NFC technology really motivated us. We put together a quote combining a local team in Switzerland and competitive pricing, and were able to win him over — of course, confirming that we would finish by the end of January 2021!

We then had a month to roll out the UX and mobile application design and code the two iOS and Android applications.

A recipe for success: focus and commitment

We could call this agility, lean management, or even working with ‘an MVP mindset’. But, in the end, these are only keywords used to describe the focus and commitment of those involved.

We were often asked how we would to be able to create a digital product for a client the size of Bobst in just one month. The people asking these questions thought we would have to resort to some kind of magic, as they thought we would develop a project that would usually take two to three years in just four weeks.

But our recipe for success is very straightforwarde. In fact, we can describe it in six main points:

- The key decision-maker for the product leads the project (and not their boss’s boss’s boss...)

- The key decision-maker understands the meaning of an MVP — i.e. a streamlined roadmap aggressively prioritised in to deliver the solution a client wants in one to two months instead of five years.

- The key decision-maker has authority and can manage all parties involved (for example, the marketing department, the IT department, etc.)

- The parties integral to the project (i.e. the internal back-end developers) are involved in the project from day one and have time specifically dedicated to the project.

- The key decision-maker organises tests with real clients straight after the first release to see if the solution responds to their needs.

- The entire team working on the project (employees from both the client and Liip) focus solely on this unique project for four weeks, coming together daily to manage any issues that arise.

They may seem obvious, but these points are far from the norm. And yet, it is thanks to these key points that we were able to roll out the Bobst TooLink mobile application in only four weeks.

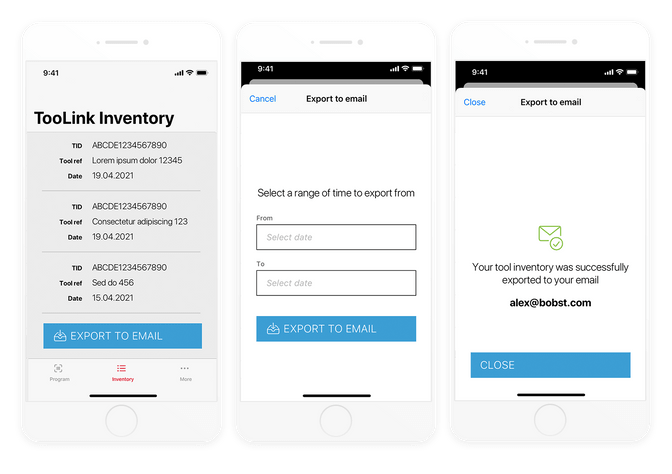

Data export functionality, directly from the Bobst TooLink mobile application

So, what is next?

The mobile application is still being tested in real conditions, and Alexandre is collecting and prioritising the feedback on it. As a result of the feedback we have received, we will adjust the initial roadmap and have additional two-weeks iterations to develop the most requested functions.